- Machinery design

- Product standardization

- Sheet metal, CNC, and prototyping design

- Manufacturing cost optimization

- Mentoring and training for mechanical designers

- Industrial layout conception and P&I diagram

- Building site supervision

Cocotubaru specializes in designing a wide range of machinery, including automation systems, packaging equipment, material handling systems, precision mechanical systems, and food & beverage machinery. What sets us apart from our competitors is our unique combination of expertise, creativity, and dedication to delivering exceptional results.

- Customization: We understand that each client has specific requirements, and we excel at tailoring our designs to meet their unique needs. Our team works closely with clients to understand their objectives, ensuring that the machinery we design perfectly aligns with their goals.

- Innovation: We pride ourselves on staying at the forefront of technological advancements. By leveraging the latest tools, software, and techniques, we bring innovation to every project. Our solutions are not only efficient and reliable but also incorporate cutting-edge features that enhance performance and productivity.

- Experience and Expertise: With years of experience in the field, our team of engineers possesses extensive knowledge and expertise in mechanical design. We have successfully delivered projects across various industries, gaining valuable insights and skills that allow us to tackle complex challenges with confidence.

- Quality and Reliability: We prioritize quality and reliability in all aspects of our work. Our meticulous approach to design ensures that every detail is carefully considered, resulting in robust and durable machinery.

- Collaborative Approach: We believe in strong collaboration with our clients throughout the design process. By fostering open communication and active involvement, we ensure that their vision and requirements are effectively translated into the final product. Our client-centric approach guarantees satisfaction and successful outcomes.

At Cocotubaru, we strive for excellence in every project we undertake. Our commitment to delivering superior machinery, combined with our technical prowess and client-centered approach, makes us the preferred choice for all your design needs.

Product standardization refers to the process of establishing a set of consistent specifications, features, and design elements for a particular product or range of products. It aims to streamline manufacturing processes, improve efficiency, reduce costs, and ensure consistent quality across the product line.

Cocotubaru offers a range of services related to product standardization to help businesses optimize their operations and achieve greater consistency and cost-effectiveness. These services include:

- Product Assessment: Cocotubaru can assess your existing product line and evaluate the potential for standardization. Our team will analyze the various components, features, and manufacturing processes to identify areas where standardization can be implemented effectively.

- Design Optimization: We work closely with clients to optimize the design of their products, ensuring that the standardized features and components meet the desired specifications. Our expertise in mechanical design allows us to identify opportunities for improvement, such as reducing complexity, enhancing functionality, and maximizing manufacturability.

- Component Selection: Cocotubaru assists in selecting standardized components that meet the required quality standards and specifications. We collaborate with trusted suppliers and manufacturers to source off-the-shelf components or develop custom components that align with the standardized design.

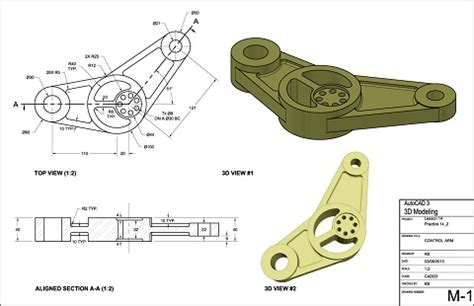

- Documentation and Guidelines: We provide comprehensive documentation and guidelines for product standardization, including detailed specifications, engineering drawings, assembly instructions, and quality control procedures. These resources serve as a reference for manufacturing teams, ensuring consistency and adherence to standardized practices.

By leveraging product standardization, businesses can benefit from increased efficiency, reduced manufacturing costs, improved quality control, and enhanced customer satisfaction. Cocotubaru’s services in this area enable clients to achieve these advantages by implementing standardized designs and processes that align with their specific industry requirements.

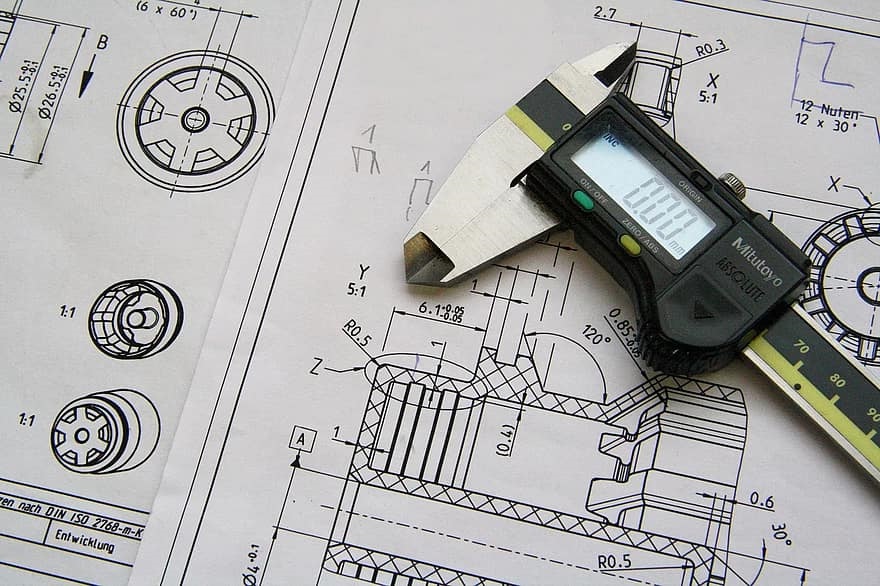

Cocotubaru offers a range of services related to sheet metal design, CNC milling and turning design, and prototyping design. Here are the services we provide in these areas:

- Sheet Metal Design: Our expert engineers specialize in designing sheet metal components and structures. We utilize advanced CAD software to create precise 3D models and generate detailed drawings and flat patterns for fabrication. Our designs optimize material usage, manufacturability, and assembly processes.

- CNC Milling and Turning Design: Cocotubaru excels in designing components for CNC milling and turning processes. We leverage our expertise to create intricate 3D models and generate machining instructions. Our designs focus on achieving high precision, dimensional accuracy, and efficient production.

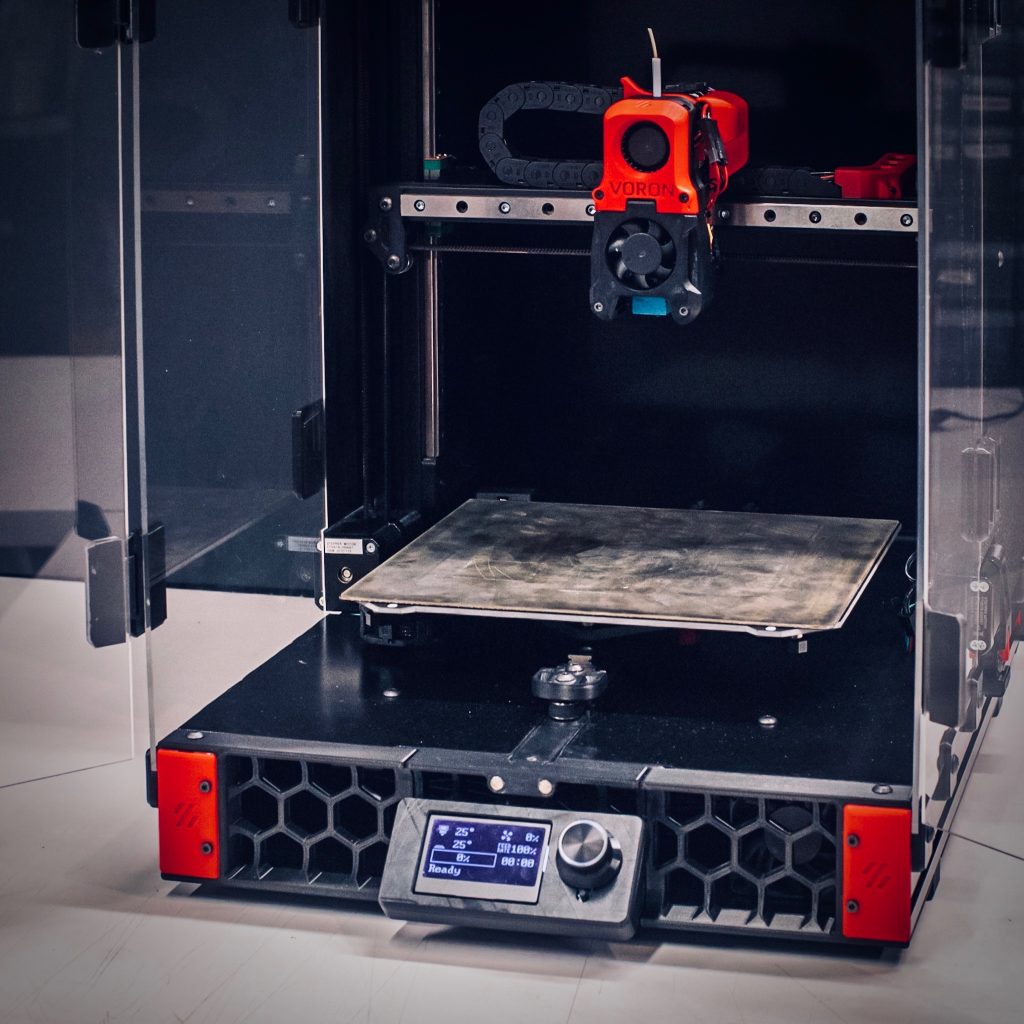

- Prototyping Design: We offer prototyping design services to bring concepts to life and validate designs before mass production. Cocotubaru utilizes rapid prototyping technologies such as 3D printing, CNC machining, and manual fabrication methods. We work closely with clients to refine designs, optimize functionality, and ensure the feasibility of the final product.

Our services in sheet metal design, CNC milling and turning design, and prototyping design combine technical expertise, attention to detail, and a deep understanding of manufacturing processes. Whether it’s creating sheet metal components, optimizing CNC machining operations, or producing functional prototypes, Cocotubaru provides comprehensive design solutions to meet client requirements and achieve optimal results.

Cocotubaru employs various strategies to optimize costs in the manufacturing process. Here are some approaches we use:

- Design for Manufacturability (DFM): Our engineers focus on designing products that are easy to manufacture, assemble, and maintain. By considering manufacturing constraints and processes during the design phase, we can eliminate unnecessary complexities, reduce material waste, and streamline production.

- Standardization: We promote the use of standard components, materials, and processes whenever possible. Standardization helps minimize costs by leveraging economies of scale, reducing the need for custom-made parts, and simplifying sourcing and production logistics.

- Value Engineering: Cocotubaru applies value engineering principles to identify opportunities for cost reduction without compromising product quality or functionality. We analyze different aspects of the design, materials, manufacturing processes, and supply chain to identify cost-saving alternatives while maintaining or enhancing performance.

- Supplier Collaboration: We work closely with suppliers to optimize costs throughout the supply chain. By fostering strong relationships and open communication, we can negotiate favorable pricing, explore alternative materials or components, and improve lead times and delivery schedules.

- Process Optimization: Cocotubaru analyzes and optimizes manufacturing processes to increase efficiency, reduce cycle times, and minimize waste. Through lean manufacturing principles and continuous improvement initiatives, we identify bottlenecks, implement process enhancements, and optimize resource utilization to achieve cost savings.

Overall, Cocotubaru’s cost optimization strategies revolve around efficient design, standardization, value engineering, supplier collaboration, process optimization, and quality control. By incorporating these principles into our approach, we help clients achieve cost-effective manufacturing solutions without compromising on quality or performance.

Cocotubaru offers comprehensive training and mentoring programs for mechanical designers, empowering them with the skills and knowledge required to excel in their roles. Here’s how we can assist in training and mentoring mechanical designers:

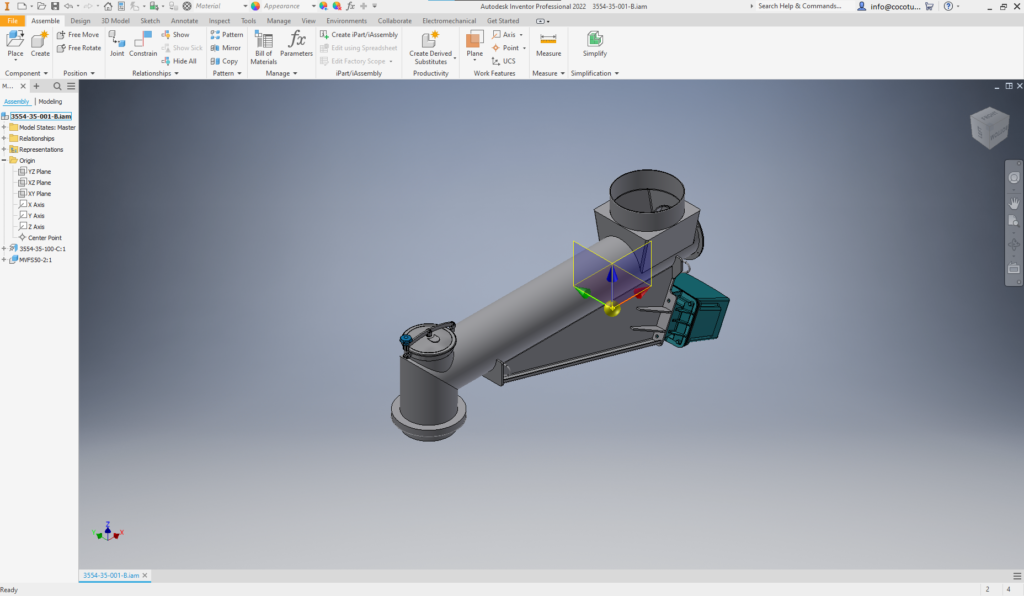

- Technical Training: We provide in-depth technical training programs that cover various aspects of mechanical design, including CAD software proficiency, engineering principles, material selection, and design best practices. Our training sessions are tailored to meet the specific needs and skill levels of designers.

- Software Proficiency: Cocotubaru offers training on Autodesk Inventor. We focus on enhancing designers’ proficiency in this tool, enabling them to create accurate, easy modifiable and efficient designs.

- Design Standards and Practices: We educate designers on industry design standards and practices to ensure compliance and enhance design quality. This includes guidelines for component selection, tolerance analysis, design for manufacturability, and design for assembly.

- Problem-solving Techniques: Cocotubaru mentors designers in developing effective problem-solving skills. We guide them in identifying and resolving design challenges, optimizing designs for performance and efficiency, and overcoming obstacles throughout the design process.

- Design Review and Feedback: Our experienced mentors conduct design reviews, providing constructive feedback to designers to enhance their design skills and promote continuous improvement. We offer guidance on design optimization, manufacturability, and cost-effectiveness.

- Industry Knowledge and Trends: Cocotubaru keeps designers updated with the latest industry trends, technological advancements, and emerging design practices. We share industry insights and knowledge to broaden their perspective and inspire innovative design thinking.

By offering training and mentoring programs, Cocotubaru enables mechanical designers to expand their knowledge, improve their design capabilities, and grow as professionals in the field. Our focus on practical skills, industry standards, and continuous improvement equips designers with the tools they need to succeed in their roles.

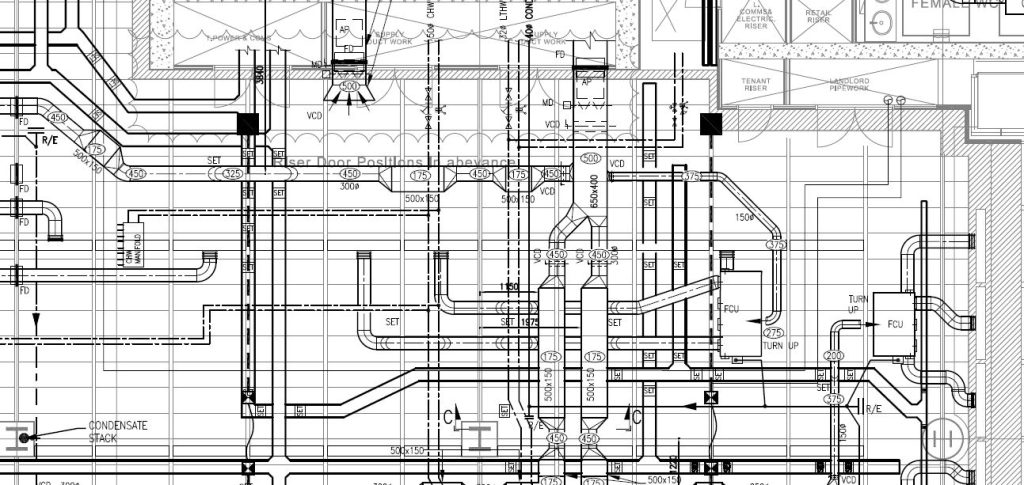

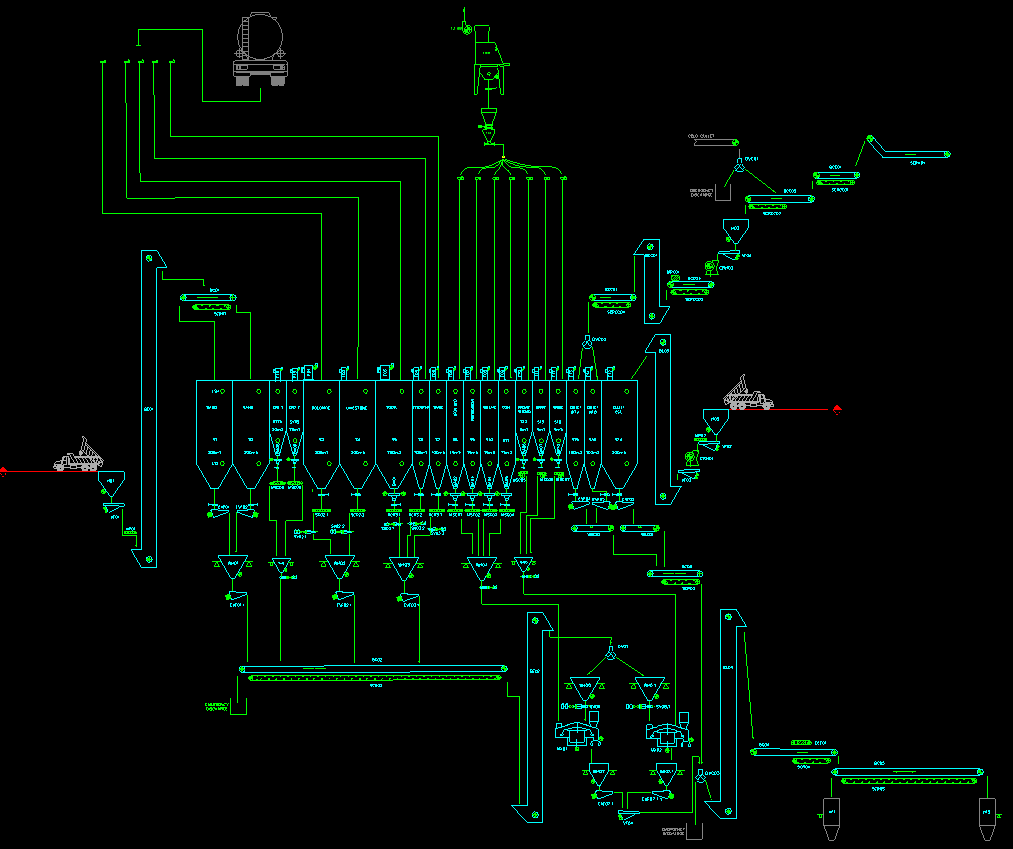

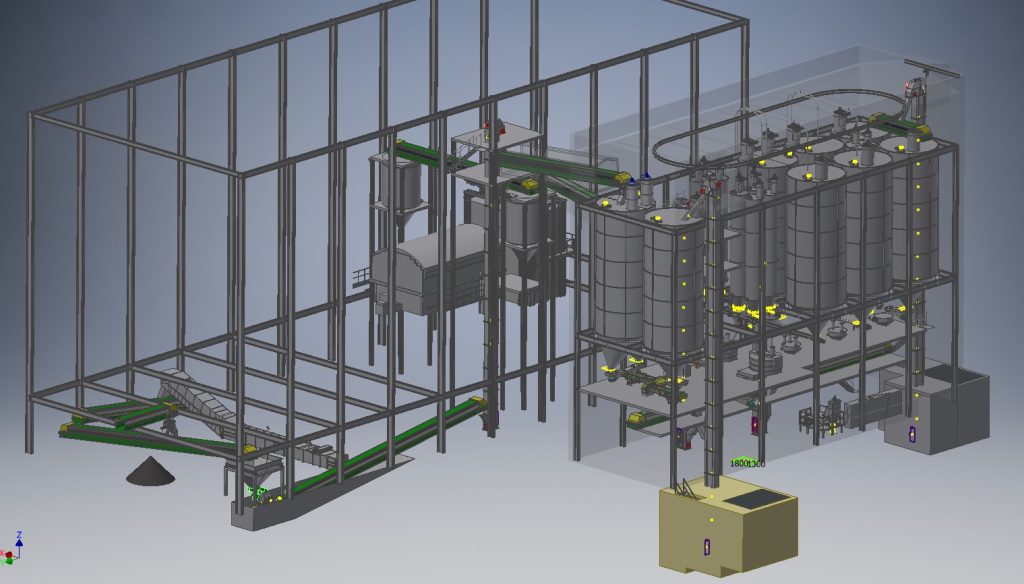

Cocotubaru offers comprehensive services in plant layout and P&I (Piping and Instrumentation) diagram design. Our expertise in this area allows us to provide the following services:

- Plant Layout Design: Cocotubaru can assist in designing the optimal layout for industrial facilities, taking into account factors such as workflow, equipment placement, material flow, safety regulations, and space utilization. We create detailed 2D and 3D plant layout drawings that visualize the arrangement of machinery, workstations, storage areas, utilities, and other key elements.

- Process Flow Analysis: Our team conducts a thorough analysis of your production processes to identify bottlenecks, inefficiencies, and areas for improvement. We optimize the flow of materials, equipment, and personnel to enhance productivity, minimize downtime, and streamline operations.

- P&I Diagram Development: Cocotubaru specializes in creating accurate and detailed P&I diagrams that illustrate the interconnections of piping, instrumentation, and equipment in industrial processes. Our diagrams provide a clear representation of process flows, control systems, instrumentation, and safety measures, ensuring effective communication and understanding among stakeholders.

- Equipment Placement and Sizing: We assist in determining the optimal placement and sizing of equipment within the facility, considering factors such as accessibility, maintenance requirements, safety considerations, and workflow efficiency.

- Safety and Compliance: Cocotubaru prioritizes safety and compliance in plant layout design. We ensure that safety protocols, regulations, and industry standards are adhered to, minimizing potential hazards and risks.

- Documentation and Reporting: We provide detailed documentation of the plant layout and P&I diagrams, including technical specifications, equipment lists, and material flow charts. These documents serve as valuable references for project stakeholders, maintenance teams, and regulatory authorities.

Cocotubaru’s plant layout and P&I diagram services enable clients to optimize their facility design, enhance operational efficiency, improve safety, and ensure compliance with industry standards. With our expertise and attention to detail, we deliver customized solutions tailored to each client’s specific requirements.

Our Building Site Supervision service is designed to ensure your construction project is completed on time, within budget, and to the highest standards. Our experienced team provides vigilant oversight of your building site, guaranteeing that every aspect of the project is executed correctly and efficiently.

- Operator Compliance: We conduct regular security checks to ensure that all operators are trained, certified, and comply with safety regulations, minimizing the risk of accidents and ensuring a safe working environment.

- Design Integrity: Our team verifies that the building work is carried out in accordance with approved drafts and designs, ensuring that the final product meets your exact specifications.

- Material Management: We monitor stock levels and manage material deliveries to ensure that your project has the necessary resources to progress smoothly, preventing delays and cost overruns.

- Effective Mediation: We facilitate open communication and mediation between clients and contractors, ensuring that any issues or disputes are resolved quickly and efficiently, and that the project stays on track.

- Visual inspection: Our team conducts regular visual inspections to ensure that the work is being carried out to the highest standards, identifying and addressing any defects or deficiencies promptly.

- Schedule Management: We monitor the project schedule, ensuring that all milestones and deadlines are met, and that any delays are minimized and communicated to all stakeholders.

By entrusting our Building Site Supervision team with your project, you can have confidence that every detail will be meticulously managed, and your construction project will be completed to the highest standards of quality, safety, and efficiency. Our neutral and impartial approach ensures that the interests of all parties are represented, and that the project is delivered to your satisfaction.